Ingress Protection (IP) Testing

Will your parts survive that rain storm or dust getting in?

What is IP Testing?

Ingress Protection testing, or IP testing, tests a product’s ability to protect against ingress of some description. That really means the ability of the outer casing to protect against the access of water, dust and solid objects to the internal workings and to prevent people from accessing hazardous parts of a product. Some of the standards related to IP testing include MIL-STD-810, RTCA/DO-160, and IEC 60529/EN 60529.

Read More

IEC 60529 describes an internationally recognised system for classifying degrees of protection provided by enclosures. Ultimately, these standards can be used to test your systems against ingress of solid bodies, dust, and water. The result of the test is an IP coding that helps to define the extent to which an enclosure provides protection for:

- persons against access to hazardous parts,

- equipment against ingress of solid foreign objects

- equipment against harmful effects due to ingress of water

IP Coding

The IP code for any particular enclosure will depend on the nature of the product and its application.

The IP code consists of two numerals and may include additional and supplementary letters.

The first characteristic numeral indicates degree of protection against access to hazardous parts and against solid foreign objects. The second characteristic numeral indicates of protection against ingress of water.

Portable electronic equipment used outdoors may have a rating of IP67 or IP68 – dust tight, and resistant to temporary or continuous immersion. This would now be common for mobile phones, for example.

Read more

Domestic appliances which could be exposed to moisture or splash water might have an IP44 rating – protected against objects over 1mm in size, and splashing water.

Automotive parts may have ratings of IP66 or IP69 – dust tight and resistant to powerful water jets or high pressure and temperature water jet.

The IP code can be applied to any enclosure where it is important to demonstrate protection against access to hazardous parts, ingress of dust or foreign objects, or ingress of water from drips, sprays, splashes, jets or immersion.

Protection against ingress from solid objects (Including sand and dust protection testing)

Openings in enclosures, such as fans and vents in electronic equipment can allow solid bodies a pathway to enter. In many cases these openings can attract dust and dirt to be ingressed. As a result, dust can accumulate inside the device and create product lifetime and safety issues. Dust testing is often required for medical devices and consumer electronics, or even military products and mining and construction equipment.

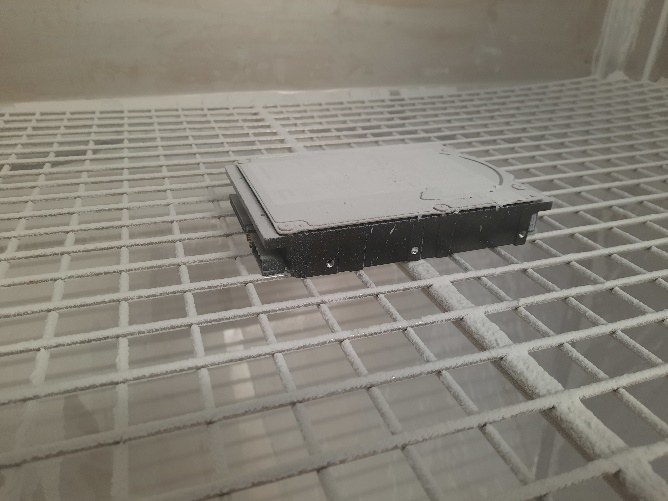

Testing for solid body ingression can be anything ranging from 50mm probe testing through to fine dust testing with the equipment under negative pressure. At the finer scale it is important to determine if the product will still be able to function if some dust has got through the casing, or in some cases that the enclosure is completely dust tight, stopping the possibly of any dust reaching the internal components.

Waterproofness testing and protection of ingress of liquids

Waterproofness testing reduces the risk of product failure in the field by simulating conditions where a product may be subjected to contact with water, and determining what may happen.

Technology that claims to be waterproof has become a big trend in recent years. But how do you know how protected your device is? Most devices use an IP rating. High-end smart phones, tend to have an IP67 or IP68 rating. Some can even go up to IP69, but that is more rare. Even if a smartphone has a high IP rating, it may not be completely waterproof. You can drop a phone with an IP68 rating in a freshwater pond, or a tub, and it should be fine. However, if that phone is dipped in a chlorinated pool, or in the ocean, which has saltwater, that could cause problems.

The rubber seals that usually protect a high IP-rated phone from water damage could be weakened over time. That could decrease the device’s overall water resistance. Those same seals can erode if a smartphone encounters coffee, soft drinks, or champagne spills.

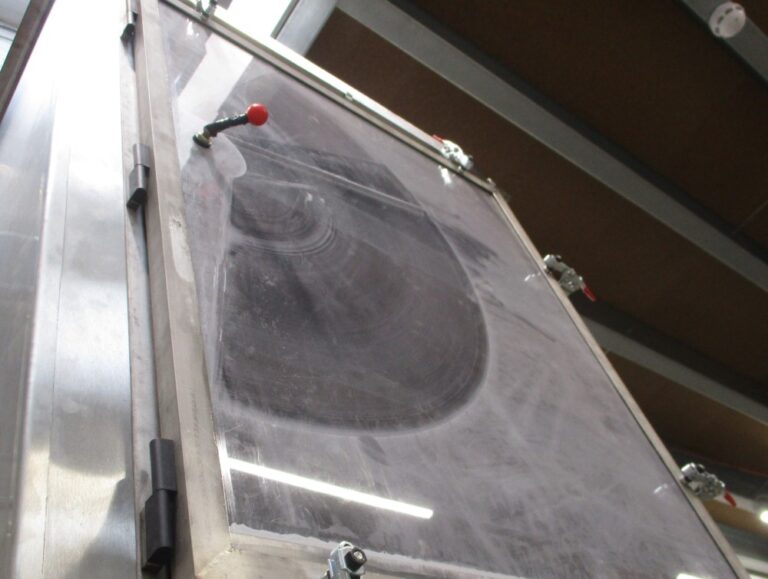

Water ingress testing uses high tech simulation equipment to ensure that seals and enclosures can give the required protection from dripping water (rain), sprays, powerful water jets and even full immersion testing under a required depth of water.

Resonate testing offers waterproof testing along with all our other environmental testing services. We are experienced in many industry standards including ISO 20653 and IEC 60529 which outline the procedures and ratings for ingress protection testing.

How can Resonate Testing Ltd. help you?

Resonate Testing can help you gain the confidence that your product is protected against ingress of solid foreign objects and water. We can carry out a range of water ingress and dust ingress protection tests.

Our water ingress testing facilities are flexible to accommodate a wide range of enclosure sizes, from small electronic enclosures to large walk-in equipment cabins.

Tests for protection against ingress of water range from water drips through water spray, water splash and water jets, to water immersion.

Our dust machine working space is 1.4m3. This enables dust protected and dust tight tests, with option for enclosure pressure depression during test.

Furthermore, we are capable of in-house manufacturing of mechanical fixtures according to customer specific design.

Lastly, our tests are performed according to the appropriate standards and a full report can be provided with images of the test set-up and results.

Our ingress protection test capability builds on Resonate Testing’s existing expertise in mechanical, dynamic, and environmental testing across industry sectors.